Green and Clean Powder Coating: Our Commitment to Sustainability

Maas Brothers Powder Coating's Commitment to Reduce Scope 1, 2, and 3 Emissions by 15% by 2030

If you have watched our new Sustainability Story video (see below), or read the other related information on our website, you know that Maas Brothers Powder Coating has long embraced a practical approach to sustainability that focuses on strategic equipment investments and other process improvements that help us reduce waste while maintaining quality work. We just never tried to put a number on the related emissions impact... until now.

We are currently committed to reduce Scope 1, 2 and 3 emissions by at least 15% each by 2030 compared to a 2018 benchmark. This aligns with our larger customers who need to better understand our emissions to measure their own Scope 3.

Sustainability reporting, including emissions measurement, is a journey. We have started by measuring 2023 data while we also measure and define our 2018 benchmarks. The good news is that early calculations confirm that our equipment upgrades, operating improvement initiatives and other ongoing efforts to reduce waste are paying off. We are even hopeful to increase our reduction commitments as a result. Look for updates soon!

Maas Brothers Delivers Beautiful, Eco-Friendly Industrial Metal Coating Solutions

As Northern California’s largest stand-alone industrial powder coating business, Maas Brothers is committed to sustainability and constantly improves its processes to ensure you get the cost-effective and time-efficient ecologically-friendly powder coating results you need for your metal coating jobs of all sizes, from production runs to prototypes.

We go above and beyond to minimize our impact on the environment as well as our carbon footprint. Our integrated powder reclaim systems ensure that wasted material is kept to a minimum, while our closed-loop no-drain wash system guarantees that no chemicals or contaminants ever leave our facility. In addition, we always try to hire locally to both support our local community as well as reduce our employees’ commute carbon footprint.

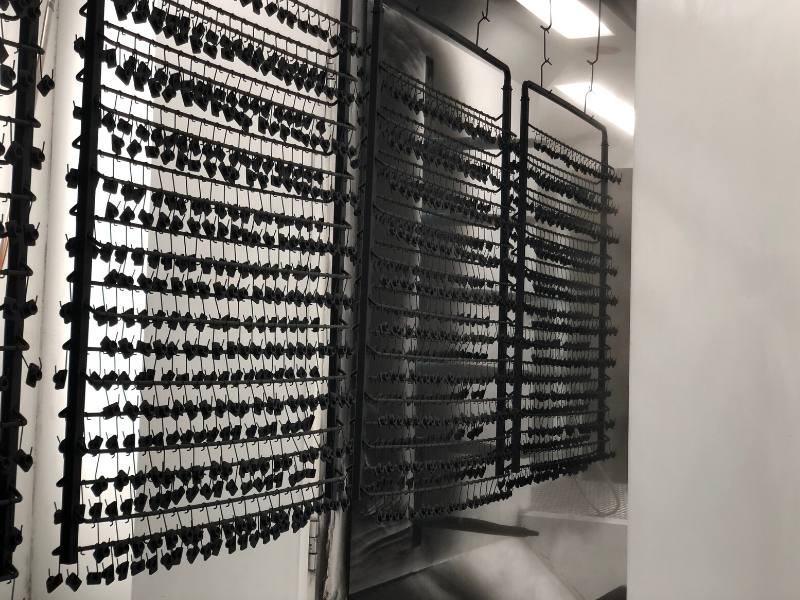

Through all of our in-house industrial metal finishing services, Maas Brothers actively pursues lean manufacturing best practices to save energy, reduce waste and improve productivity. Over the years we have actively refined every step of our production process, looking for every opportunity to save resources and reduce waste. This includes everything from cleaning and reusing our hooks and bars to recycling and reusing packing materials whenever possible.

Essentially, all of those hyphenated adjectives mean that Maas Brothers’ pre-production washing system is as environmentally friendly as it can be.

The five-stage washing process ensures that contaminants are scrubbed clean from your products before they are sent down the line for powder coating. Meanwhile, our closed-loop no-drain system ensures any potentially hazardous byproducts are not released from our facility. The system also filters and reuses water, with a net loss of only ~1 gallon per minute due to evaporation.

Our state-of-the-art quick color change booth allows us to reclaim powder for many of our jobs, reducing your costs while ensuring the utmost efficiency and sustainability for your project. Our powder recapture processes save up to 50% of powder that would otherwise go to waste.

Maas Brothers is an RoHS Compliant domestic powder coater. This ensures our industrial metal finishes are clean and safe for your customers while allowing your products to meet other regulatory requirements that your market may demand.

Maas Brothers leverages quick color change capabilities, powder reclaim systems, and in-line priming to save your project time and money while consistently making your commercial metal parts look better and last longer. Simultaneously, we strive to minimize waste and maximize efficiency at every step of production.

Increase your commitment to environmental sustainability the easy way: Pick the right powder coater for your project!

The first two metal coating decisions you make matter most when it comes to reducing the environmental impact of your project:

Decision #1: The type of coating you specify for your metal project.

Just specifying powder coating for your metal parts goes a long way to helping the environment. With its solvent-free process, powder coating is the most ecologically-friendly coating option compared to solvent-based options like liquid painting.

Decision #2: The powder coater you hire.

How an industrial powder coater runs their shop, the efficiency of the equipment they invest in, their commitment to recycling water, the protocols they follow for material use and disposal, how they package coated products, and even how clean the shop is — it all matters to the durability, beauty and long-term sustainability of your project as well as its impact on the environment.

So does being able to match the right powder coating process to your project needs. When your project qualifies for a state-of-the art automated powder coating process like Maas Brothers offers, you’ll access even more efficiencies — saving time, materials, money, and yes — environmental impact.

In addition, a strong commitment to project quality control reduces reworks and material waste, too.

How will you know which powder coater is the best to hire?

Ask to take a tour of their facility — and ask lots of questions! We recommend a tour even if you’ve been working with the same powder coater for a decade. Our industry has been changing. Not everyone is keeping up. A fresh look is always worth it.

When you compare powder coaters based on what you see and how they answers questions you know are important, clear differentiators are easy to spot. Your decision becomes obvious.

Eco-Friendly Automated Powder Coating Services

On Time. Any Color. Finished On Spec.

Maas Brothers is one of Northern California’s fastest, most reliable, flexible, and cost-effective automated powder coating service providers. Our conveyorized system streamlines numerous pre-treatment and coating processes in a single run. Our automated processes are uniquely engineered to deliver superior quality and consistency with every metal part we finish.

Capable of providing high-performance metal finishes and functional powder coating solutions, Maas Brothers’ automated line is able to accommodate even the most challenging industrial and commercial powder coating applications, including batteries coating and other functional coatings requiring HiPot testing.

The Advantages of Our Automated Powder Services:

- Two fully automated conveyor systems that accommodate parts up to 12.5 ft.

- Computer-automated spray booths ensuring consistency of both color and film thickness.

- New state-of-the-art quick color change booth provides rapid 10-minute color change-outs with integrated powder reclaim capabilities.

- Integrated pre-treatment and in-line priming capabilities streamlines the entire finishing process.

- In-line Infrared (IR) pre-gelling ovens for advanced two-stage powder coating projects.

- Multi-stage closed loop cleaning, washing and sealing capabilities.

- Numerous well-lit inspection stations for quality assurance and accuracy.

- Value-added production services including blasting, masking, plugging, and light assembly.

- Expert color-matching capabilities

Streamlined Commercial Metal Coating Solutions Optimized for Your Products:

With quick color-change technology, built-in IR get ovens and large part capabilities up to 12.5 ft in length, our facility is equipped to tackle your next unique powder coating project with the quality and speed your project needs.

ISO 9000 Compliant

RoHS and REACH Compliant

AAMA 2605, 2604 and 2603 Certified Applicator

- AKZO Certified

- IGP Certified

- IFS Certified