Automated Powder Coating Services in Livermore, CA

On Time. Any Color. Finished On Spec.

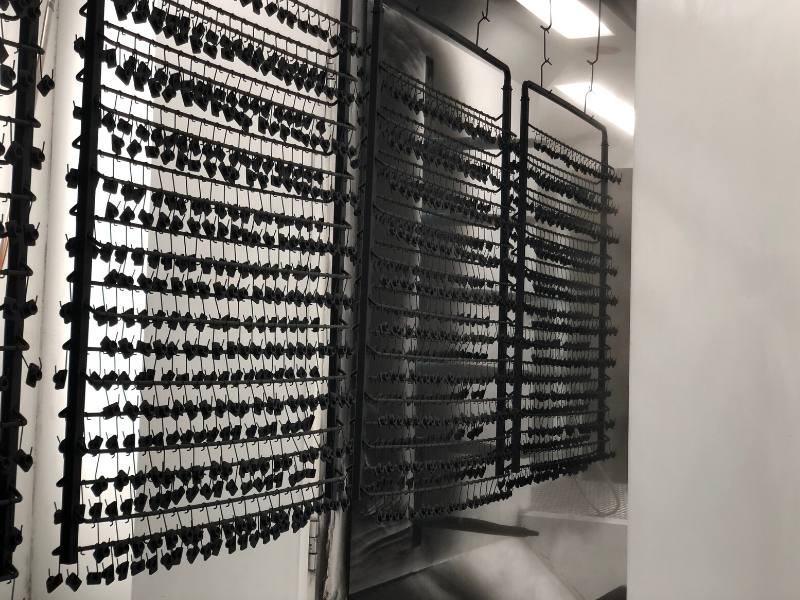

Maas Brothers is one of Northern California’s fastest, most reliable, flexible, and cost-effective automated powder coating service providers. Our conveyorized system streamlines numerous pre-treatment and coating processes in a single run. Our automated processes are uniquely engineered to deliver superior quality and consistency with every metal part we finish.

Capable of providing high-performance metal finishes and functional powder coating solutions, Maas Brothers’ automated line is able to accommodate even the most challenging industrial and commercial powder coating applications, including batteries coating and other functional coatings requiring HiPot testing.

The Advantages of Our Automated Powder Services:

- Two fully automated conveyor systems that accommodate parts up to 12.5 ft.

- Computer-automated spray booths ensuring consistency of both color and film thickness.

- New state-of-the-art quick color change booth provides rapid 10-minute color change-outs with integrated powder reclaim capabilities.

- Integrated pre-treatment and in-line priming capabilities streamlines the entire finishing process.

- In-line Infrared (IR) pre-gelling ovens for advanced two-stage powder coating projects.

- Multi-stage closed loop cleaning, washing and sealing capabilities.

- Numerous well-lit inspection stations for quality assurance and accuracy.

- Value-added production services including blasting, masking, plugging, and light assembly.

- Expert color-matching capabilities

Streamlined Commercial Metal Coating Solutions Optimized for Your Products:

With quick color-change technology, built-in IR get ovens and large part capabilities up to 12.5 ft in length, our facility is equipped to tackle your next unique powder coating project with the quality and speed your project needs.

ISO 9000 Compliant

RoHS and REACH Compliant

AAMA 2605, 2604 and 2603 Certified Applicator

- AKZO Certified

- IGP Certified

- IFS Certified