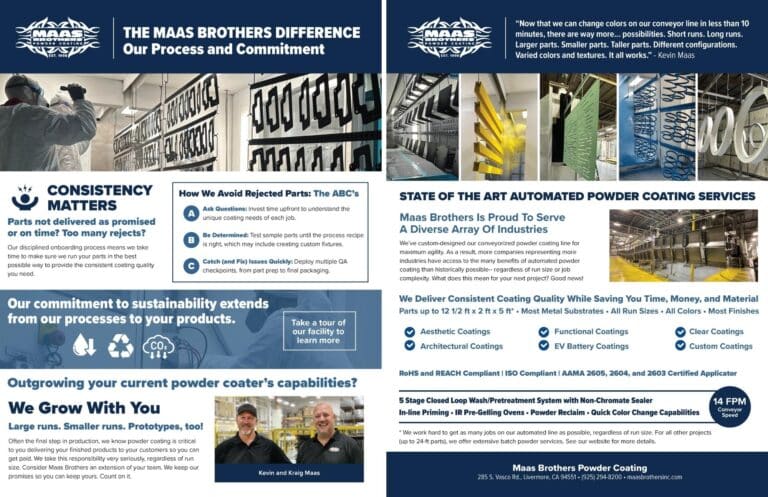

Industrial Metal Coating & Commercial Finishing Services in Northern California

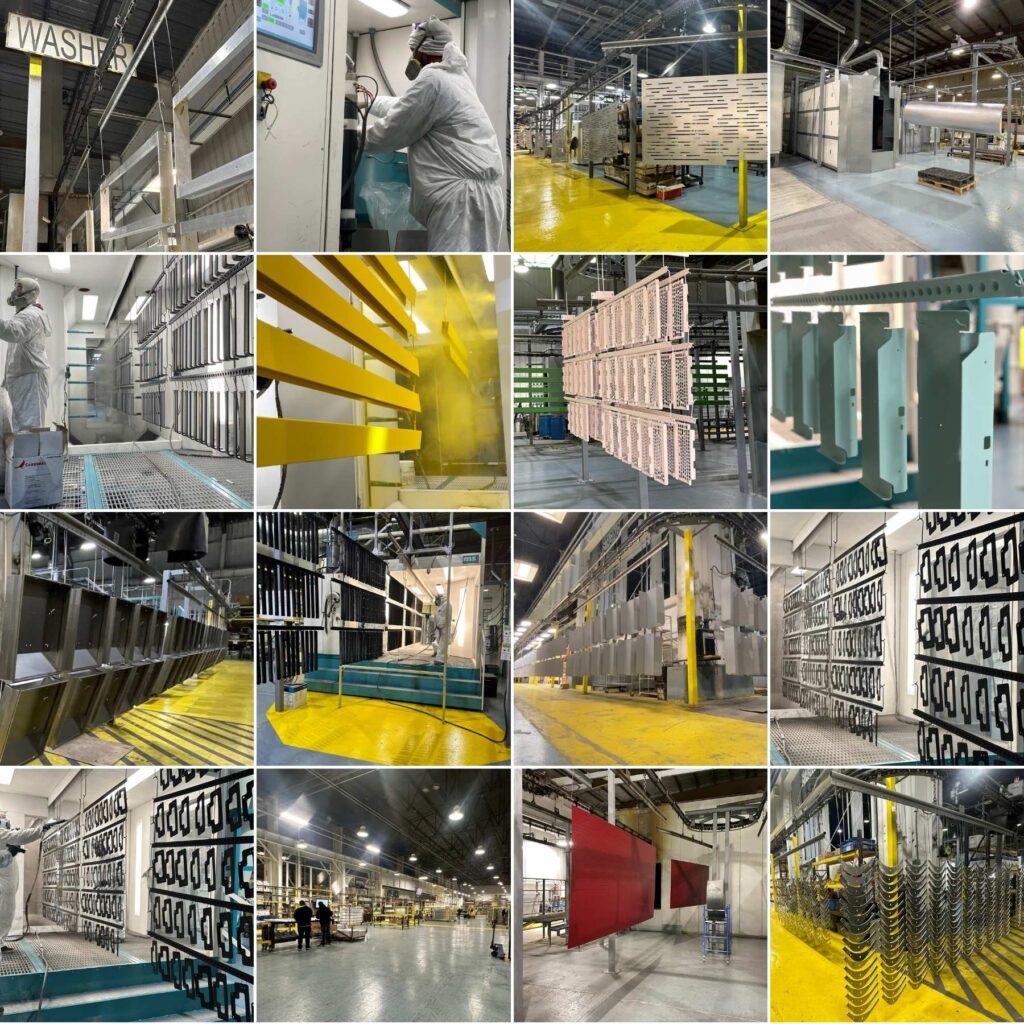

The Maas Brothers Automated Powder Coating Line

Metal Coating Services That Save You Time, Money, and Material While Delivering the Consistent Metal Coating Results You Need

Maas Brothers Offers RoHS and REACH Compliant Metal Coating Solutions

Customized Automated Line Means More Options for You

Our advanced conveyorized metal powder coating line capabilities is custom-designed for maximum flexibility to handle a wide variety of metal coating needs.

- Ability to coat metal parts up to 12.5 feet by 5 feet by 2 feet

- RoHS and REACH Certifiable processes

- Multi-stage closed-loop cleaning, washing, and sealing for superior adhesion

- In-line priming and other two coat capabilities

- Automated spray booths for precise color and film thickness control

- Maximum color flexibility with quick color change booth and powder reclaim technology

- Infrared (IR) ovens for efficient pre-gelling and curing

Customized Process Recipes for Consistent Metal Coating

Our state-of-the-art equipment investments help ensure the uniform, high-quality finish for large-scale production projects, part after part.

The key is how we deploy those capabilities by blending our more than 25 years of metal coating expertise to achieve maximizes customer satisfaction and consistent coating quality, while minimizing rejects.

That starts with asking the right questions so we are clear about your needs for your project, studying the parts, and then testing processes until we’ve defined the best “process recipe” needed. That includes everything that happens to each part, from the time we receive it for coating until we pack it for delivery back to you.

Cost and Time-Saving 2-Coat Inline Coating Options

Our conveyorized powder coating system is custom-designed for maximum agility with in-line infrared (IR) ovens for pre-gelling between 2-coat needs and/or minimizing cross-contamination in the curing oven when we are running multiple colors on the line. This saves you money, time and materials.

Example 2-coat needs:

- Primer + Top Coat applications for superior durability

- Thicker powder coat layers requiring multiple coats for non-standard thickness

- Functional coatings, including EV battery coatings

- Color coat + Clear coat for added protection and aesthetic appeal

- Other specialized 2-coat need

Industrial Metal Coating and Commercial Finishing for a Variety of Metal Substrates

We work with customers to powder coat projects using a wide variety of metal substrates, including aluminum, and steel, among others. Click here for a list metal substrates we powder coat.

Get a Quote for Your Industrial Metal Coating & Commercial Finishing Projects

Whether you need industrial metal coating for high-volume production or repeatable short-run metal coating projects that fit on our automated powder coating line — or your project is better suited for batch process powder coating, Maas Brothers has the expertise and capabilities to deliver the exceptional metal finishing results you need.

The Maas Brothers Powder Coating Difference Flyer

Need More Industrial Metal Finishing Options — Or Commercial Finishing for Non-Metal Projects?

Our Advanced UV LED Printing Services May Be The Answer!

In addition to traditional metal powder coating services, Maas Brothers offers UV LED printing for metal parts, providing a durable, high-resolution finish for decorative and branding applications. This advanced technology is ideal for custom graphics, logos, and detailed prints on a variety of metal substrates. For customers looking to enhance their coated parts with branding, functional markings, or faux finishes, UV LED printing provides a flexible and cost-effective solution that can be used in combination with powder coating or as a standalone option.

Unlike powder coating, which offers durability and protection, UV LED printing allows for detailed, full-color imagery, barcodes, and precise surface designs that traditional powder coatings cannot achieve. Additionally, UV LED printing can be applied to non-metal substrates, making it a great option for projects that involve mixed materials or require a highly customized aesthetic.